Issue(s):

- LongMill will bind when cutting or jogging

- Y-axis is skewing when moving

- Cuts are not correct

- LongMill stops in the wrong spot

- LongMill is cutting in wrong area

Resolution:

Mechanical

If the machine is randomly binding or stalling when jogging or running a job, the issue is likely mechanical.

1. Power OFF the machine.

2. Rotate the leadscrews by hand. They should all rotate with equal, consistent resistance. If they rotate very freely, something needs to be tightened up. If they are stuck, something needs to be loosened.

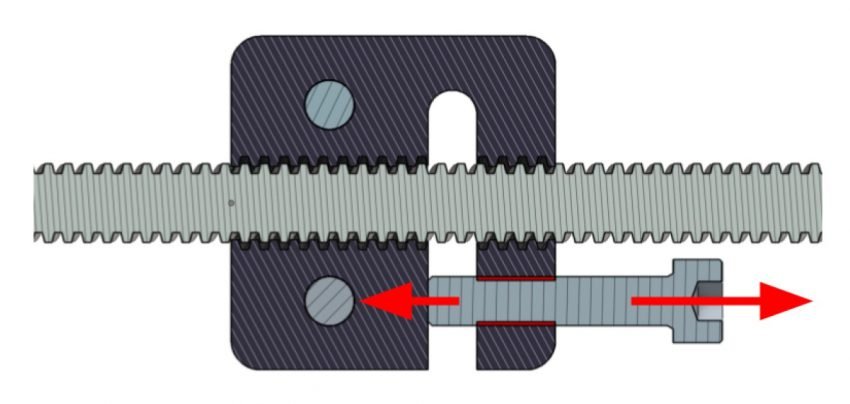

- Backlash nuts - Adjust the tension using the small screw attached to the nut.

If there is a lot of tension on the leadscrews, loosen the two mounting screws holding the backlash nut to the metal gantry.

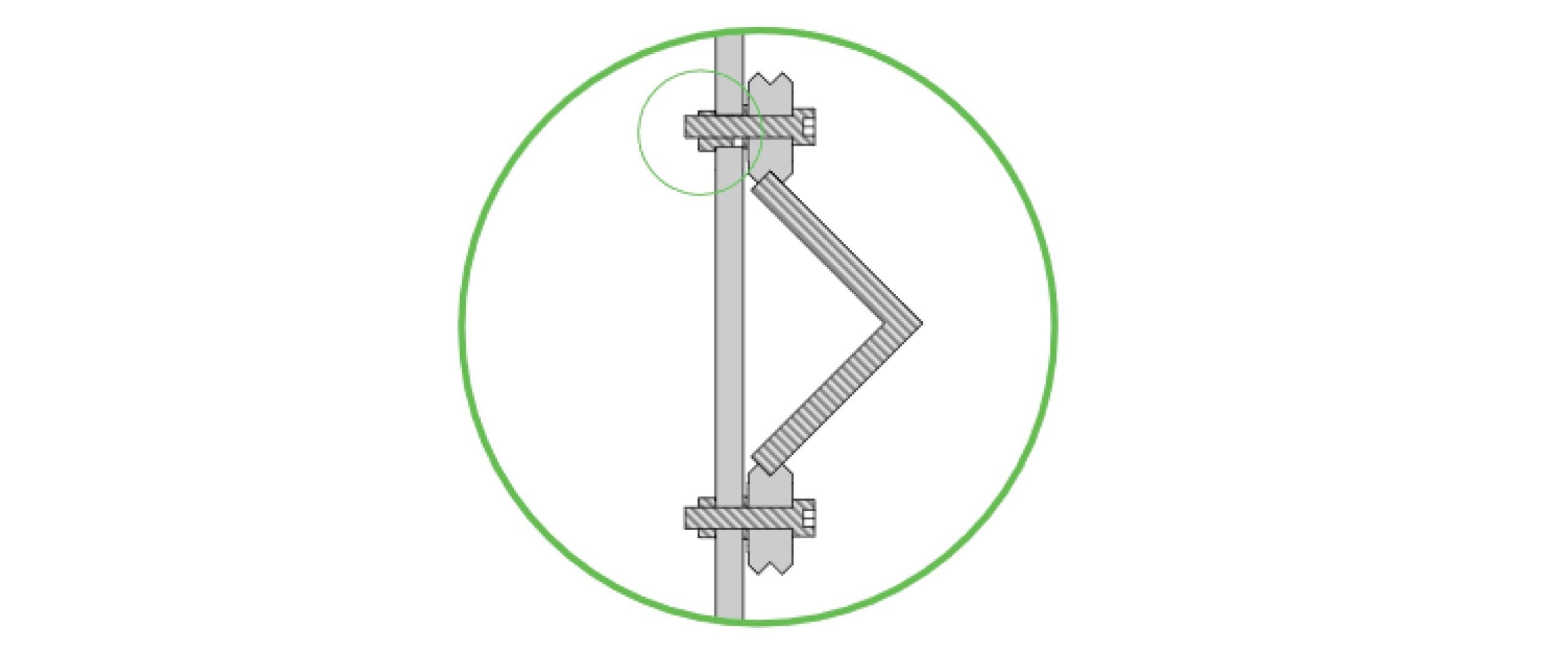

- V-wheels - If there is any slack / play in the gantries, the v-wheels might be loose and not contacting the rails correctly. Adjust the eccentric nut so that the v-wheels fit in the groove on the rail. It's more important that all wheels rotate and there is no looseness in the gantry, versus all wheels having the same tension.

- Motor Coupler - Make sure the coupler is tight on the leadscrew and the motor shaft. If it loosens again after tightening it is possible the hole has stripped.

- ACME nut - Check that the nut is secured against the Y-gantry. If it loosens again after tightening it is possible the hole has stripped.

3. For LongBoard - Check DIP switches and potentiometers, switches should be UP-DOWN-UP-DOWN and potentiometer should be pointed to 2.2A as shown in picture.

4. For Y-axis skewing - After making adjustments, run the machine to the back until you hear a grinding noise, this will realign your Y-axis gantries to be square with the X-axis. See if the issue is still persisting by jogging back and forth, moving through the entirety of the Y-axis travel.

Post Processor

If the machine is cutting inaccurately and you see the error "motion command target is invalid" then most likely you have the wrong post processor selected.

Use the grbl post processor in millimeters. You can find this setting in the CAM software you use (Vectric VCarve, Fusion360)

The error occurs due to how grbl firmware handles arc commands in imperial units.

#longmill #tuning #binding #cutting-issues