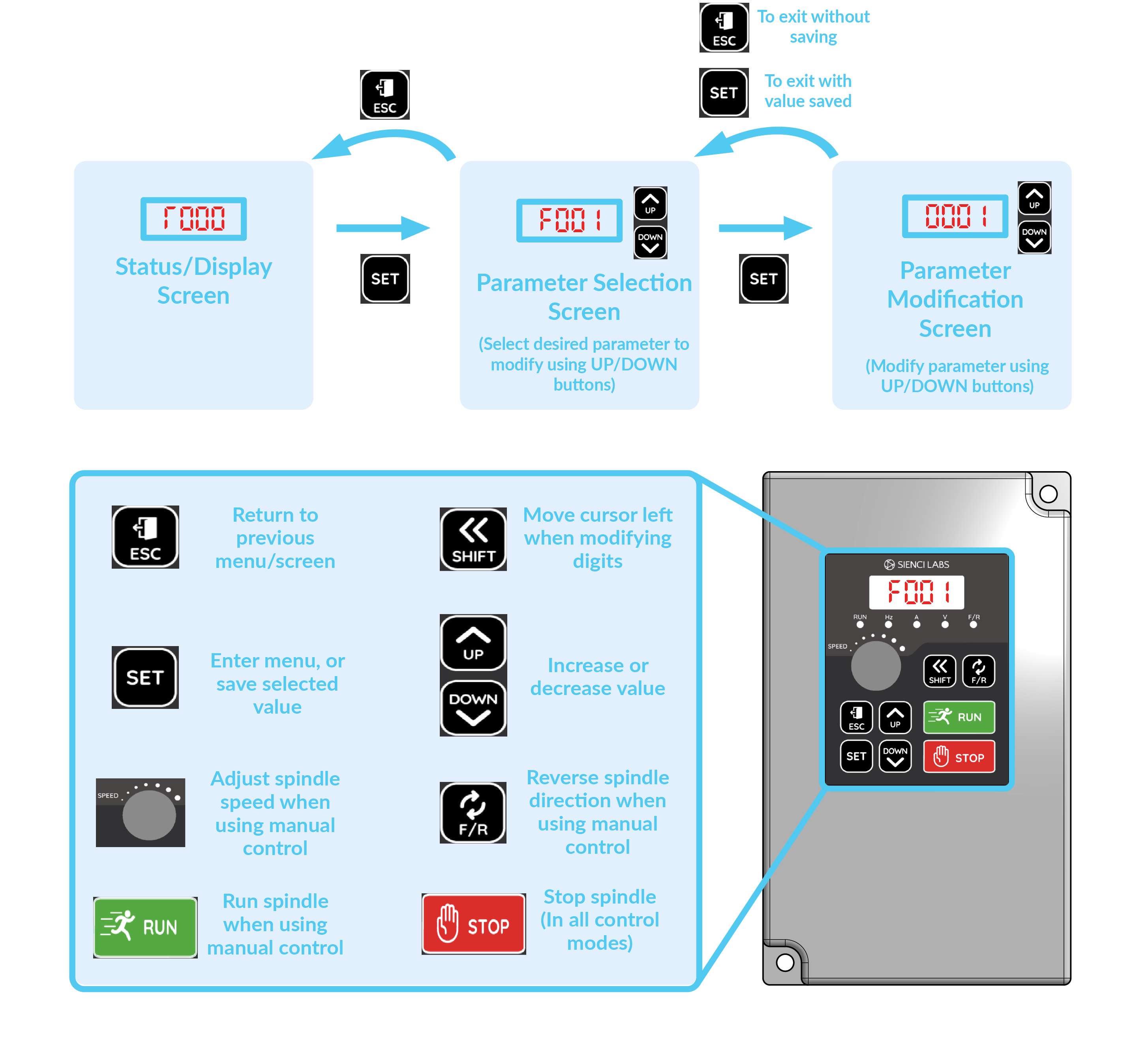

To modify values, press the ‘SET’ button to enter the parameter selection screen. Here, you’ll see parameters ranging from F000 to F199. Use the UP and DOWN buttons to select the parameter you’d like to modify, then press ‘SET’ to select that parameter.

Once in the parameter you’d like to change, use the UP and DOWN buttons to modify this. When done, press ‘SET’ again, to save the value and exit the parameter modification screen. If you’d like to exit the screen without saving the modified parameter, press the ‘ESC’ button instead.

While the Sienci Labs spindle kit is set up by default for control using RS485 serial communication, it is possible to use PWM (pulse width modulation) to control the operation and speed of your spindle instead. This can be useful if you’re having trouble using RS485 communication for any reason, or if you’re setting up this kit on a machine that does not have RS485 communication capability.

To set up control for machines such as the SuperLongBoard, or original LongBoard, you’ll want to set these parameters on your VFD panel, following the process described above:

PWM Parameter Settings

| Parameter | Value | Name of Parameter | Description |

| F001 | 1 | Control Mode | Sets external input terminal to trigger run/stop of spindle |

| F002 | 1 | Frequency Setting Selection | Sets spindle speed to be controlled by the A|1 input terminal |

| F070 | 1 | Analog Input Selection | Designates A|1 input to use a 0-5V control signal |