This troubleshooting guide is for both the AltMill and LongMill using either the SLB or the SLB-EXT.

Issue(s):

- An Alarm 14 appears and won't clear

- An Alarm 14 happens when starting a job

- An Alarm 14 appears at startup

- r00.0 on VFD

This would point to an error in how you’ve set up your spindle physically, how you’ve set up the SLB EEPROM values, or how you’ve set up the PD values on your VFD.

Troubleshooting Lights

Confirm both communication LEDs are flashing when connected to the VFD. If only one or none of the LEDs are flashing, there is a communication issue either with the control board, the VFD, or the RS485 cable. (#4 and #5 on the diagram).

Resolution:

Startup Procedure

Alarm 14 during startup (or the spindle not spinning) comes on usually when you don’t turn on the controller and spindle in the correct order. The controller and VFD need to “handshake” and if the conditions aren’t met, even if they’re on at the same time they won’t go through with the handshake.

Assuming the controller is plugged into power but turned OFF:

1. Plug spindle into power, the VFD should blink with red text

2. Then turn on the controller using the power toggle

This is the correct way to turn on your controller, each time, to avoid Alarm 14.

Restore Default Configuration

- Download the setup file AltMill_Sienci_Spindle_Configuration__SLB-EXT or LongMill Spindle Configuration (SLB Controller only)

- Open gSender and run the attached setup code. This will set all EEPROM settings to what they should be

- Power cycle everything. Turn off the VFD and the controller. Close gSender

- Turn on the VFD first, then the controller, then connect to gSender.

- Ensure the VFD is plugged into the back of the controller above the power switch.

- Go to console, type $spindles and check if H100 is selected as “Current spindle”.

- In Console, type M3S10000 to see if the spindle spins properly.

-

In Console, type M5 to see if the spindle stops.

RS485 Wiring

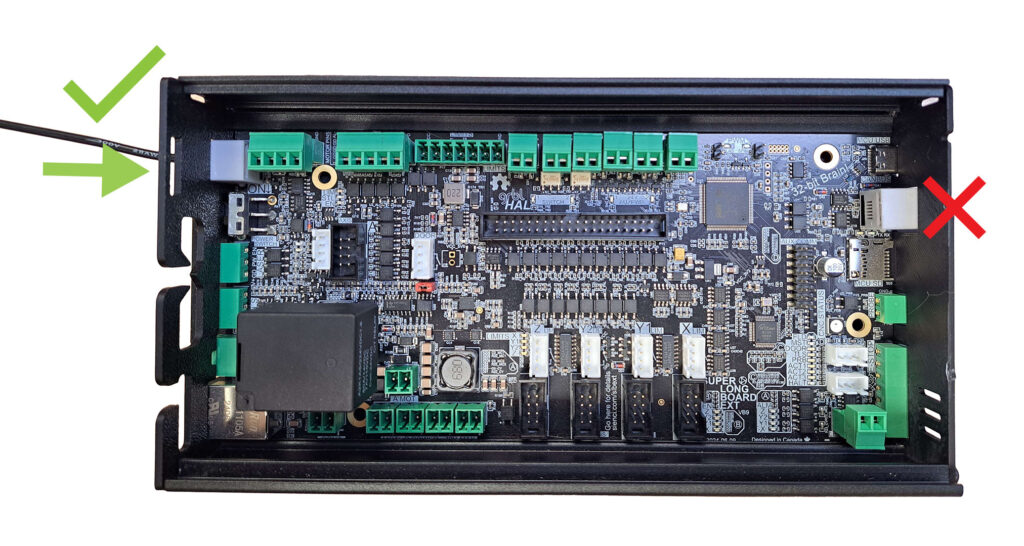

First please ensure you have plugged in the RS485 cable in the correct port on the SLB. The RS485 cable should be plugged into the connector above the OFF-ON switch and NOT the connector below the USB cable.

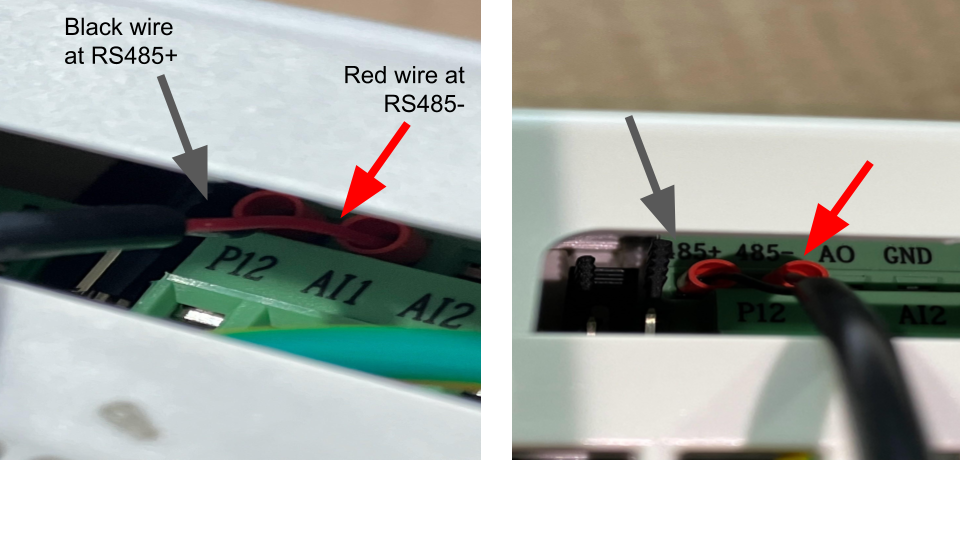

Ensure that the RS485 cable is wired correctly at the VFD side, and plugged into the telephone jack on the SLB-EXT. The red wire goes to RS485-, and black goes to RS485+. If you need to modify this, make sure to unplug the VFD from power first.

Troubleshoot the RS485 Cable

To test if the cable is the issue, please do the following:

Remove the green 4-pin connector from the control board, located beside the RS485 jack. Using 2 strand wire, install the wires as shown. In my example, the red wire is connected to the 485+ on the VFD and to the A pin on the green connector. Black is wired into the RS485- on the VFD and the B pin on the green connector.

Then run the default configuration setup above.

AltMill_Sienci_Spindle_Configuration__SLB-EXT or LongMill Spindle Configuration (SLB Controller only)

If the spindle moves the cable isn't the issue and will need to be replaced. If the spindle doesn't start, the issue could be on the VFD or the control board. Reach out to customer support for next steps.

MODVFD Setup

If the above does not solve the issue, a workaround would be to use MODVFD as the default spindle. This should work for spindles that communicate using RS485, such as the Sienci Labs Spindle (H-100), Huanyang, Durapulse, and Yalang. See instructions here.